Look around you. Observe any of the objects that are close to you. Look at the screen of your computer or your smartphone. The materials used to make these items have been developed by humans. And, in this creative process, nature has been and continues to be a great source of inspiration [1], [2].

For example, the gecko’s feet, which exhibit incredible non-slip properties, are being studied for producing materials useful in the footwear industry [3]. Cicada wings, which possess super hydrophobicity, have inspired the development of antibacterial surfaces for medical and surgical equipment [4]. Mother-of-pearl, which is strong and lightweight, has provided inspiration for the creation of numerous materials [5].

But despite these advances, many properties of natural materials remain difficult or impossible to incorporate into synthetic ones. Natural materials are produced by living organisms, capable of growing, repairing themselves, sensing and adapting to their environment… and this is where nature’s superiority lies. For example, the mechanical virtues of silk lie not only in its chemical structure, but also in other factors such as fibre orientation and hydration. Spiders, in response to their environment, modify these features and are able to produce different types of silk fibres designed for different functions [5].

What if we could infuse these abilities into the materials we use every day? Recent advances in synthetic biology and materials science have given rise to a new era of advanced materials that fulfil these characteristics: self-ventilating sportswear, self-healing surfaces, bioplastics that dissolve after use, or implants for the long-term and personalised delivery of drugs to the body are just a few of the functions that can be achieved by so-called engineered living materials (ELMs). These materials are created by programming living organisms not just to produce a particular material, but to become an integral part of it!

Coding cells for material mastery

We already leverage microbial cell factories to make many of the things we interact with on a daily basis [2]. There are countless examples: bacterial species that produce cellulose, the key component of wood and paper [2], [6]; new ways to produce nylon [7], widely used in the pharmaceutical industry; or alternatives to synthesise polysaccharides such as alginate and chitin, useful for a wide range of applications from agriculture to medicine [2].

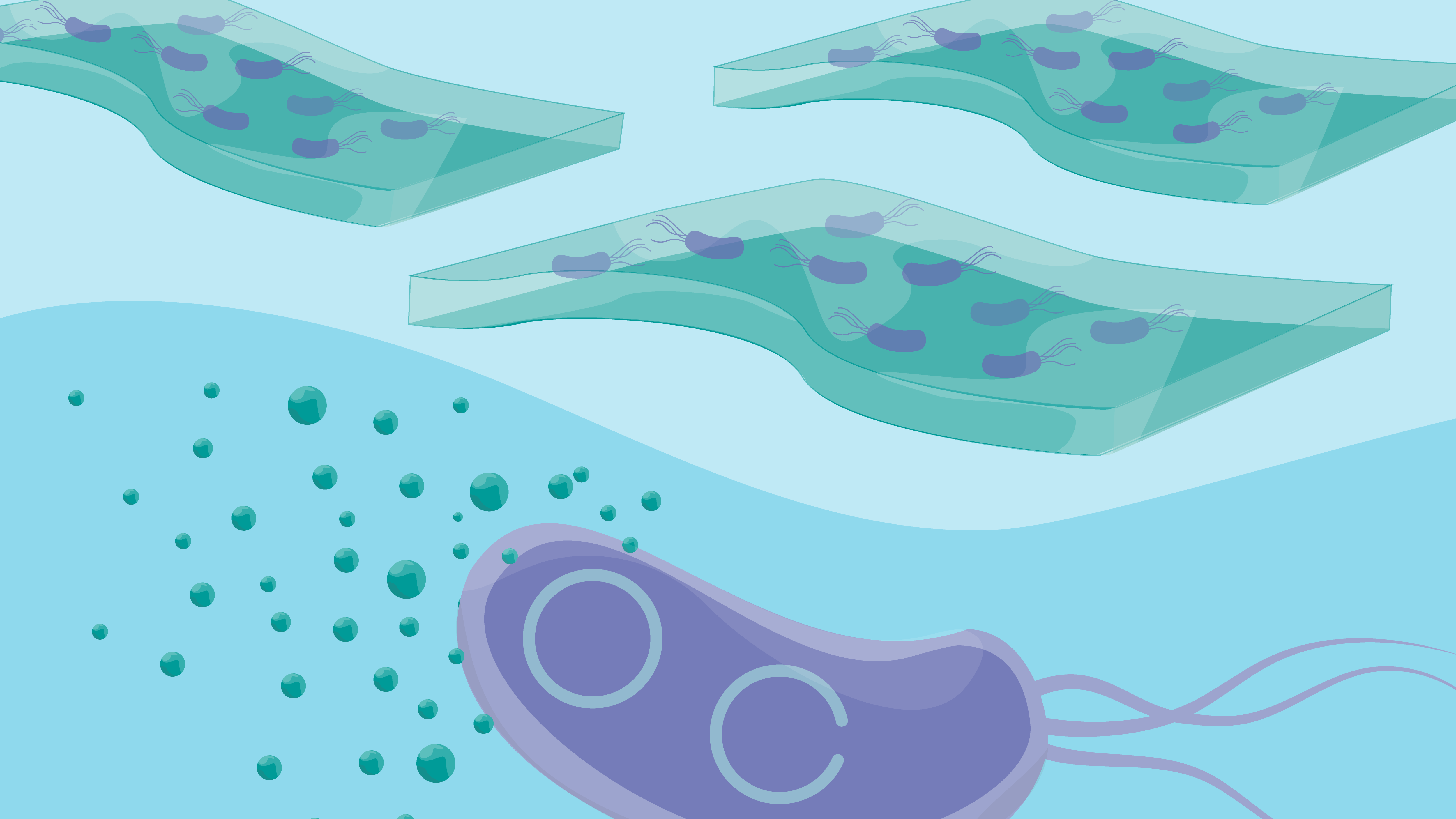

However, synthetic biology could provide a tool not only to manufacture the basic ingredients of new materials, but to become part of them, thus making the extraordinary organisational and architectural power of nature available to us. Biomaterials made by living systems, though very diverse, often share a similar organisation: different lineages of cells are precisely arranged within a matrix to create a hierarchically defined structure. This meticulous organisation gives them multifunctional properties that often exceed those of traditional materials. Moreover, these living cells are able to grow, regenerate when damaged and adapt to changing environments. As a result, there is growing interest in creating engineered living materials (ELMs) that have capabilities similar to those of natural living materials, but with tailored functions [8].

These materials can be composed entirely of living cells or combine living and synthetic components. Bacteria, fungi, and even eukaryotic cells in some cases, are genetically modified to provide them with the desired programmability and responses [9]. Examples include wound-healing gels containing genetically modified bacterial spores that produce antibiotics when they detect pathogenic bacteria; or regenerative living building materials, which are not only tough and durable, but can also regenerate and adapt to environmental conditions [9]. Other applications of MLEs are being explored in areas such as electronics and energy, with the development of biological batteries that use genetically modified bacteria to generate electricity from sugars and other organic compounds [10].

A collaborative journey into the future

The possibilities are endless, but challenges are also huge. To achieve this reality, we need a deeper understanding of the molecular rules governing biological assembly, more advanced biological engineering tools, and rigorous study of the long-term robustness, feasibility and safety of these materials. And all of these challenges require a joint effort by materials engineers, molecular biologists, geneticists, and other experts, who must work together to learn to speak nature’s language and share her tools [5], [9].

References

- Gilbert, C., & Ellis, T. (2020). Engineered living materials: prospects and challenges for using biological systems to direct the assembly of smart materials. Advanced Materials, 32(24), 1906000. https://doi.org/10.1002/adma.201906000

- Amaro, T. M. M. M., Rosa, D., Comi, G., & Iacumin, L. (2019). Prospects for the use of whey for polyhydroxyalkanoate (PHA) production. Frontiers in microbiology, 10, 992. https://doi.org/10.3389/fmicb.2019.00992

- Fedit. (2017, May). Suelas antideslizantes basadas en las patas del gecko. Retrieved from https://fedit.com/2017/05/suelas-antideslizantes-basadas-en-las-patas-del-gecko/

- Atria Innovation. (n.d.). Biomimetic materials: What are they? Retrieved from https://www.atriainnovation.com/en/biomimetic-materials-what-are-they/

- Studart, A. R. (2018). Towards high-performance bioinspired composites. Advanced Materials, 30(37), 1707169. https://doi.org/10.1002/adma.201707169

- Singh, A., Walker, K. T., Ledesma-Amaro, R., & Ellis, T. (2020). Engineering bacterial cellulose by synthetic biology. International Journal of Molecular Sciences, 21(23), 9185. https://doi.org/10.3390/ijms21239185

- Kruyer, N. S., & Peralta-Yahya, P. (2017). Metabolic engineering strategies to bio-adipic acid production. Current Opinion in Biotechnology, 45, 136-143. https://doi.org/10.1016/j.copbio.2017.03.006

- Nguyen, P. Q., Courchesne, N. M. D., Duraj-Thatte, A., Praveschotinunt, P., & Joshi, N. S. (2020). Engineered living materials: Opportunities and challenges for using biological systems to direct the assembly of smart materials. Advanced Materials, 32(24), 1906000. https://doi.org/10.1002/adma.201906000

- Materials come alive. (2022). Nature Materials, 21, 379. https://doi.org/10.1038/s41563-022-01234-0